Technology

Why More and More Brands Are Turning to 3D Printing

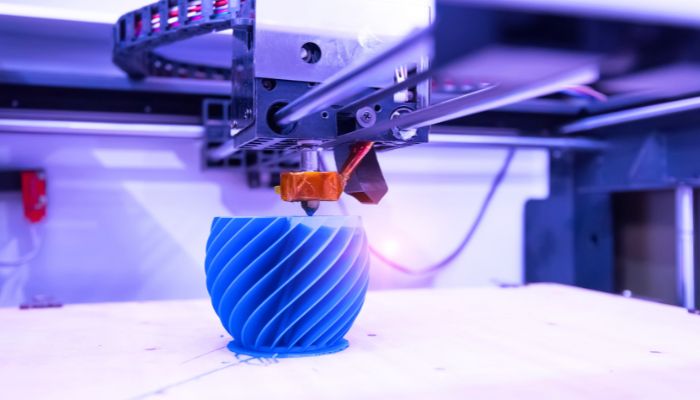

In recent years, the landscape of manufacturing and product development has been undergoing a significant transformation, with 3D printing at the forefront of this revolution. Brands across various industries are increasingly adopting 3D printing technology, recognizing its potential to revolutionize their production processes, enhance creativity, and meet evolving consumer demands. This shift towards additive manufacturing is not just a passing trend but a strategic move that’s reshaping the future of production and brand innovation.

One of the primary reasons brands are embracing 3D printing is the unparalleled flexibility it offers in product development and customization. Traditional manufacturing methods often require significant time and resources to create prototypes or small batches of products. In contrast, 3D printing allows brands to rapidly prototype and iterate designs, significantly reducing the time-to-market for new products. This agility is particularly crucial in industries where consumer preferences change rapidly, such as fashion, consumer electronics, and automotive sectors.

The ability to produce complex geometries and intricate designs that were previously impossible or prohibitively expensive with traditional manufacturing methods is another compelling reason for brands to adopt 3D printing. This capability opens up new possibilities for product design and functionality, allowing brands to create unique, innovative products that stand out in the market. For instance, in the automotive industry, companies are using 3D printing to create lightweight yet strong components, contributing to improved fuel efficiency and performance.

Customization and personalization have become key differentiators for brands in today’s market. 3D printing enables mass customization, allowing brands to offer personalized products at scale without significantly increasing production costs. This level of customization was previously only available for high-end, luxury items, but 3D printing is democratizing this capability across various price points and product categories.

Sustainability is another crucial factor driving brands towards 3D printing. As consumers become increasingly environmentally conscious, brands are under pressure to adopt more sustainable production methods. 3D printing offers several environmental benefits, including reduced waste, lower energy consumption, and the ability to use recycled or biodegradable materials. By adopting 3D printing, brands can align their production processes with their sustainability goals, appealing to eco-conscious consumers and potentially reducing their carbon footprint.

The fashion industry, in particular, has seen a surge in 3D printing adoption. Brands are using this technology to create unique textures, intricate patterns, and even entire garments. The ability to produce on-demand and in small batches also helps reduce overproduction and inventory waste, addressing some of the industry’s most pressing sustainability challenges.

In the realm of industrial applications, 3D printing is proving to be a game-changer. Leading 3D printing manufacturer Stratasys has been at the forefront of this revolution, offering a wide range of industrial-grade 3D printers and materials. Their technology is being used across various sectors, from aerospace to healthcare, enabling brands to produce complex parts, medical models, and even end-use components with unprecedented precision and efficiency.

The automotive industry is another sector where 3D printing is making significant inroads. Car manufacturers are using additive manufacturing to produce both prototype and functional parts, reducing weight, improving performance, and enabling more design freedom. Some brands are even exploring the use of 3D printing in electric vehicle production, signaling a new era of automotive manufacturing.

The healthcare industry has also seen tremendous benefits from 3D printing. Brands in this sector are using the technology to create custom prosthetics, dental implants, and even bioprinted tissues. The ability to produce patient-specific medical devices and models is revolutionizing personalized healthcare, improving patient outcomes, and potentially reducing healthcare costs.

As 3D printing technology continues to advance, we’re seeing improvements in print speed, material options, and overall print quality. For instance, Stratasys’ J55 Prime PolyJet printer offers a rotating print platform for outstanding surface finish and printing quality, along with multi-material capabilities. These advancements are making 3D printing more accessible and appealing to a broader range of brands and applications.

The ongoing development of new materials for 3D printing is another factor driving adoption. From high-performance polymers to metal powders and even food-safe materials, the expanding range of printable substances is opening up new possibilities for brands across various industries. This material innovation is enabling the production of functional end-use parts, further blurring the line between prototyping and manufacturing.

Looking to the future, the potential of 3D printing seems boundless. Some companies are even exploring its use in space applications. Stratasys, for example, is involved in testing 3D-printed material performance on the moon, showcasing the technology’s potential in extreme environments and pushing the boundaries of what’s possible in manufacturing.

However, it’s important to note that the adoption of 3D printing is not without challenges. Intellectual property concerns, quality control issues, and the need for specialized skills are some of the hurdles that brands need to overcome. Recent developments, such as potential patent infringement cases in the US, highlight the complex legal landscape surrounding 3D printing technology.

In conclusion, the increasing adoption of 3D printing by brands across various industries is driven by its ability to offer flexibility, customization, sustainability, and innovation. As the technology continues to evolve and mature, we can expect to see even more brands turning to 3D printing to stay competitive, meet consumer demands, and push the boundaries of what’s possible in product design and manufacturing. The future of production is three-dimensional, and brands that embrace this technology early stand to gain a significant competitive advantage in their respective markets.