Lifestyle

Vivobarefoot Unveils Hybrid Wing: Pioneering Sustainable 3D-Printed Footwear

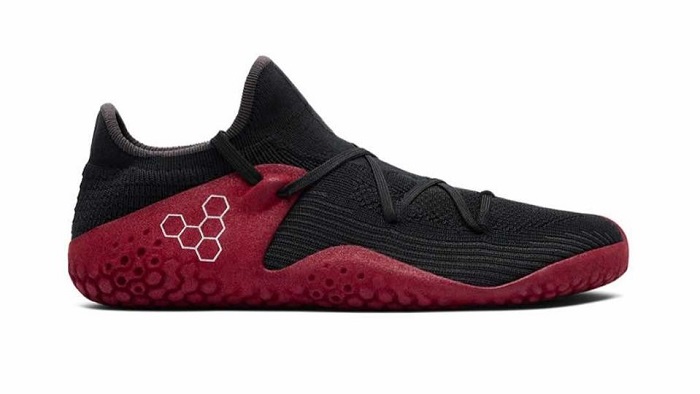

- Vivobarefoot’s Hybrid Wing is a limited edition, fully customizable 3D-printed shoe, designed for sustainability and made-to-order precision, available exclusively in the UK in two colorways.

- This model exemplifies sustainable footwear innovation through minimal material waste, automated assembly, and local production, highlighting the potential of 3D printing technology in the industry.

Vivobarefoot recently unveiled their limited edition shoe, known as Hybrid Wing. Utilizing 3D printed technology for custom fit purposes, users scan their feet using smartphones before customizing length and width with an online visualizer tool before having their 3D-printed shoes delivered within 6 – 4 months to reduce waste production by only producing them when necessary.

The Hybrid Wing fits within a growing trend in outdoor gear toward sustainable 3D printing. Utilizing circular knitting technology, its seamless 3D foot shape is created using minimal material waste; soles and uppers are attached via automated assembly using an automated glueing robot, improving production speed, accuracy and efficiency.

Vivobarefoot strives for an entirely custom made-to-order shoe model made by local producers in their own factories that is fully remade if required, like their Hybrid Wing model which features wide, thin and flexible structures suited for their distinctive barefoot shoe style. Their initial release limited to only 2000 pairs exclusively available in the UK at PS260 each and included both colorways (Obsidian Origin Red and Obsidian Origin Blue).

This approach not only reduces waste but also demonstrates the enormous potential of 3D printing for footwear manufacturing. Customizability in fit selection and material usage represent significant strides toward sustainable production practices.