Technology

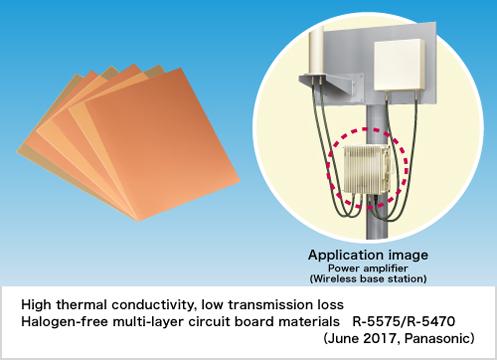

Panasonic Commercializes “High Thermal Conductivity, Low Transmission Loss Halogen-free Multi-layer Circuit Board Material” for Wireless Base Stations

Panasonic’s industry’s first halogen-free multi-layer circuit board material for power amplifiers employed in wireless base stations will contribute to the achievement of “5G” mobile communication systems.

Panasonic Corporation announced that it has commercialized its “High Thermal Conductivity, Low Transmission Loss Halogen-free Multi-layer Circuit Board Material (Part No. R-5575)” intended for wireless base stations, and will launch mass production in August 2017. The industry’s first(*1) halogen-free multi-layer board material for RF power amplifiers is designed to contribute to compact-sizing and stable operation of wireless base stations.

In the fifth-generation mobile communication system (“5G”), currently being developed for implementation in 2020, data communication by a variety of equipment such as smartphones is predicted to require a much greater capacity and higher transmission rates. For 5G communication, demand for “small cells [2] “, small base stations that can cover hot spots with high user demand, is expected to expand substantially. RF power amplifier boards used in compact-sized small cells will require a multi-layer structure to achieve further space saving in place of the current mainstream double-sided boards. The industry also requires multi-layer boards that can carry out high-speed communication in high frequency domains while providing low transmission losses as well as low heat generation. Panasonic’s proprietary resin design technology has enabled the industry’s first(*1) commercial production of multi-layer circuit board material for RF power amplifiers by providing halogen-free, low transmission loss and high thermal conductivity features that, up to this point, have represented a major technical barrier.

Panasonic’s new “High Thermal Conductivity, Low Transmission Loss Halogen-free Multi-layer Circuit Board Material” has the following features:

- The industry’s first(*1) halogen-free multi-layer circuit board material for RF power amplifiers achieves low transmission losses in the high-frequency range, enabling compact-sizing of wireless base stations.

• Transmission loss at 20 GHz: -20 dB/m(*2) - Its high thermal conductivity effectively dissipates heat from heated components used on the power amplifier to provide reliable operation.

• Thermal conductivity: 0.6 W/(m·K) (1.5 times that of the Panasonic’s conventional product (*3)) - The material protects against deterioration of transmission characteristics in high-temperature environments, thereby contributing to the long-term durability of the base stations.

• Dielectric constant [3] change rate: 1.0%, Dissipation factor [4] change rate: 3.5% (1000 hours at 125°C)

Dielectric constant change rate of current products(*4): 3.0%, Dissipation factor change rate of current products: 80% (1000 hours at 125°C)

Notes:

- *1: As a board material for wireless base stations as of June 1, 2017 (Panasonic data)

- *2: Value under the evaluation conditions (microstrip line, insulation layer 0.5 mm, circuit width 1 mm, circuit thickness 38 µm, Copper Foil 18µm , Plating 20µm)

- *3: Panasonic’s conventional product: (Multi-layer board material for ICT infrastructure , MEGTRON6)

- *4: Current product: Circuit board material for general wireless base stations

Suitable applications:

Circuit board for power amplifiers (for wireless base stations, small cell use), etc.

Remarks:

This material will be exhibited at the JPCA Show 2017 to be held from June 7 – 9, 2017 at Tokyo Big Site. This material won the 13th JPCA Award on May 19. For this award, 12 items from 10 companies were submitted. Four items were selected after rigorous testing. Panasonic has won the award for four consecutive years (11 times overall).

[Product Features]

1. The industry’s first halogen-free multi-layer board material for RF power amplifiers, achieving low transmission loss for contributing to compact-sizing of wireless base stations

Previous circuit board materials for RF power amplifiers were produced primarily with a double-sided structure and they were not designed with a multi-layer structure in mind. With communication systems becoming ever more compact, the adoption of small cells and smaller board areas is necessary, so multi-layer designs are increasingly being adopted. From an environmental viewpoint, halogen-free materials are ideal; however, alternative non-halogen flame retardant component structures tend to show considerable transmission loss in the high frequency range. Panasonic by applying its proprietary resin design technology, has commercialized the industry’s first halogen-free multi-layer board material for RF power amplifiers that is flame retardant and has low transmission loss in the high frequency range, which were difficult in the past. By achieving a multi-layer structure of 10 layers or so, usable for high-speed communication in the milliwave band of 20 – 80 GHz, it is expected to contribute to compact-sizing of wireless base stations and the achievement of 5G mobile communication systems.

[Frequency dependence of Transmission Loss]

- *The data above show actual values and are not guaranteed.

2. High thermal conductivity effectively dissipates heat from heat-generating components on the power amplifier board, thereby contributing to reliable operation.

Small cells consist of high heat generating components mounted on a relatively small electronic circuit board. Use of conventional board materials would cause the heat-generating components to become extremely hot, increasing the risk of operational instability and failure. Because R-5575 employs a highly thermally conductive resin design that disperses and dissipates the heat generated by components, temperatures can be kept low, therefore achieving stable operation of communication base stations.

3. The material contributes to the long-term operation of base stations by suppressing the deterioration of transmission characteristics that tends to occur under high-temperature conditions.

Board materials for RF power amplifiers used to be subject to the problem of deteriorating transmission characteristics when used for many hours in a high-temperature environment because they are made from resin. Panasonic’s proprietary resin technology that is used in R-5575 successfully minimizes any deterioration in dielectric constant and dissipation factor even during extended use at high temperatures. This feature is expected to preserve stable transmission characteristics and contribute to the long-term stable operation of communication base stations.

[General properties] < Part No.> Laminate: R-5575, Prepreg: R-5470

- *The data above show actual values and are not guaranteed.

[Term Descriptions]

- [1] RF power amplifier

- Apparatus for amplifying the power of the transmission signal to the required level and supplying it to the antenna.

- [2] Small cell

- A type of mobile phone base station with small output, normally used for supplementing a normal base station (macro cell). Depending on its coverage area, it is called a nano-cell, pico-cell, femto-cell, etc.

- [3] Dielectric constant

- Dielectric constant describes the ease of polarization of insulation material when an electric charge is applied from outside. Each substance has a unique value. Because easily-polarized substances readily accumulate electricity, hard-to-polarize substances (with smaller permittivity) are advantageous for effectively transmitting electrical signals. The unit of dielectric constant of a substance is relative to that of a vacuum, which is given a permittivity of 1.

- [4] Dissipation factor

- This is a unit that indicates the loss quantity when the electrostatic charge accumulated on an insulating substance is discharged. The smaller the dissipation factor, the better the discharge efficiency of the accumulated charge, and therefore the lower the transmission loss of an electrical signal.

Panasonic Corporation is a worldwide leader in the development of diverse electronics technologies and solutions for customers in the consumer electronics, housing, automotive, and B2B businesses. Celebrating its 100th anniversary in 2018, the company has expanded globally and now operates 495 subsidiaries and 91 associated companies worldwide, recording consolidated net sales of 7.343 trillion yen for the year ended March 31, 2017. Committed to pursuing new value through innovation across divisional lines, the company uses its technologies to create a better life and a better world for its customers.