Technology

3 Types of Robots Used in Manufacturing and 2 Future Developments to Look Out For

Robots are already a common sight in factories worldwide, but this is not a tech niche that rests on its laurels. To prove it, let’s look at a trio of robotic systems you can encounter in manufacturing today, and a couple of up and coming breakthroughs that are reshaping the future of this industry.

Assembly Robots

Assembly robots have become integral to many manufacturing processes. These automated machines meticulously assemble parts, often outperforming their human counterparts for speed and precision. They perform tasks such as screw driving, soldering PCBs, and part fitting tirelessly around the clock without compromising on quality or safety.

Eliminating manual assembly lines with the help of assembly robots significantly boosts productivity while minimizing errors, making this a true testament to revolutionary technology in the industry.

Material Handling Robots

Material handling robots have changed the manufacturing floor for the better, enhancing efficiency and safety.

These cutting-edge wonders can be programmed to perform tasks like moving components, packing products, picking items from conveyor belts, or loading and unloading materials.

Taking over these repetitive and often strenuous jobs lets material handling robots not only improve productivity but also prevent workplace injuries. Streamlining workforce operations while creating safer work environments make these robots an invaluable asset.

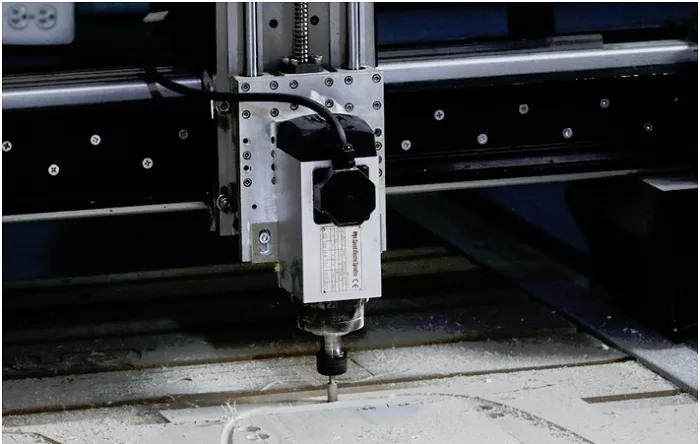

Robotic Machining Equipment

Once you understand how to get started with robotic machining, it’s easy to see its vast potential. It involves using robots that can be programmed to perform milling, drilling, and cutting tasks with a degree of precision not possible by human hands alone.

These machines are designed for complex shapes and advanced materials that may be difficult or hazardous for workers to handle. Incorporating this technology into manufacturing processes lets us once again bolster safety, precision and productivity.

A Future Forged by Collaborative Robotics

The future of manufacturing lies in collaboration, not just among human workers, but between humans and robots as well.

This exciting concept is becoming a reality thanks to advancements in collaborative robotics or ‘cobots’. These machines are designed to work safely alongside employees, often equipped with sophisticated sensors to prevent accidents.

Instead of completely replacing human workers, cobots augment their abilities. They take on the heavy lifting or repetitive tasks, freeing up employees for more complex and strategic roles. Some cobots are even being developed with machine learning capabilities that allow them to adapt and learn from humans over time.

As we look ahead, this partnership promises to both enhance efficiency and worker satisfaction in factories. There’s a long way to go before widespread adoption is viable, but we’re on that path already.

Anticipating AI-Integrated Robotic Innovations

As we enter the era of Industry 4.0, Artificial Intelligence (AI) being integrated into robots is one advance to eagerly anticipate. These ‘smart’ machines are capable of learning from their experiences and adapting to new situations, which are attributes that promise unparalleled advantages in a manufacturing context.

Some emerging applications include predictive maintenance, where AI algorithms detect potential issues before they become problems, alongside quality control, using machine vision systems for flawless product inspection beyond human capabilities.

However exciting these prospects might be, implementing this technology presents its own set of challenges, including an increase in cybersecurity risks and the need for more complex training. Yet given its transformative potential, a future with AI-integrated robotics seems as inevitable as it is game-changing.

Final Thoughts

The synergy between robotics and manufacturing continues to transform the industry. Whether through assembly robots or AI-integrated machines, we’re witnessing a future that’s more productive and safe, benefiting businesses and their employees, as well as the customers they both serve.